01

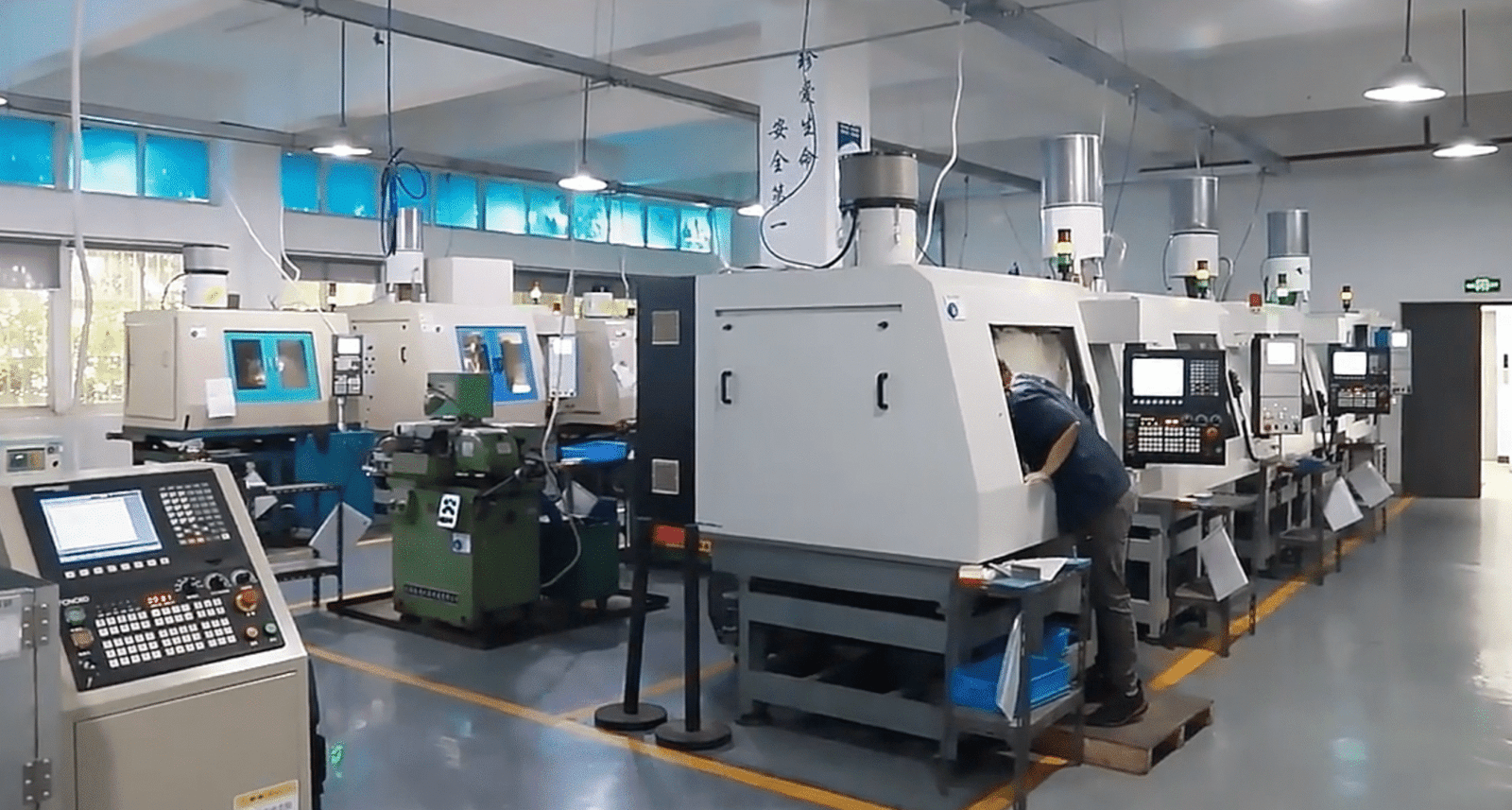

Villsin operates a modern full-cycle manufacturing plant

Villsin has a modern full-cycle manufacturing plant, with production processes ranging from the preparation of metal bars to the packaging of finished products. Our manufacturing plant is equipped with high-tech machinery from leading brands. The use of state-of-the-art equipment not only guarantees the ultimate product quality, but also makes it easy to complete the most challenging technical tasks. In addition, some machines and equipment are designed in-house and produced in our own workshops or produced by our overseas partners according to custom orders.

02

Customized employee training programs

Some processes require extreme precision and detail that even the most advanced machines cannot achieve. For example, all knife sharpening operations must be done by hand. In view of the particularities of the nail tool manufacturing industry, we have tailored training courses for our employees. After completing the training courses, our employees will have all the necessary knowledge and skills required for high-quality and efficient work.

03

Production of cutting-edge technology

With highly skilled professionals, we produce approximately 10,000 pieces per day. Our product range covers more than 20 products, professional nail drill bit tools. We produce more than 5 million products per year, and our capacity is growing every year. Villsin is the perfect combination of next-generation technology and extreme professionalism – the ultimate combination for the perfect tool.。

04

Product Quality

At Villsin, we are committed to product quality. Our production cycle covers both input and output quality assurance processes. The quality of raw materials is tested by certified laboratories, where the physical and chemical properties of the steel are analyzed. All instruments are made of top domestic stainless steel. This steel is extremely corrosion resistant and has unparalleled hardness, ensuring that the instruments remain sharp for a long time. This steel is used in both professional and home grade instruments.

Product quality assurance is the responsibility of our Quality Inspection Department. Quality inspection experts check all products for compliance with relevant regulations and standards. We are constantly improving our quality assurance process, so QC department employees regularly attend seminars and lectures hosted by well-known beauty professionals to learn the skills of using various instruments. These measures increase the thoroughness of all tests and inspections. If defects are found, the instruments will be returned for rework. This meticulous approach ensures that only high-quality products that meet all standards enter the market.

Villsin has implemented the ISO 9001 quality management system, an efficient quality management system that complies with international standards. Efficient work cycle management is a key factor in producing first-class products.